Building Information Modeling (BIM) has fundamentally changed how we design and construct buildings. It creates intelligent 3D models that provide architects, engineers, and construction professionals with the insight and tools to plan, design, construct, and manage buildings more efficiently. A crucial part of this process involves the Mechanical, Electrical, and Plumbing (MEP) systems—the complex networks that bring a building to life.

Traditionally, coordinating these intricate systems using 2D drawings was a major challenge. Engineers would layer separate plans on top of each other, trying to spot potential conflicts. This manual process was time-consuming, prone to error, and often led to clashes discovered only during construction. These on-site clashes resulted in costly delays, rework, and budget overruns.

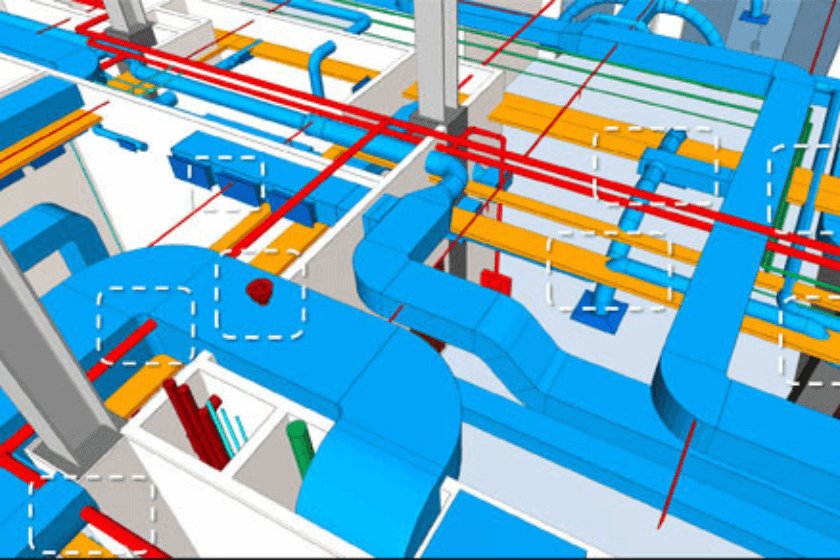

This is where 3D BIM coordination steps in. By creating a unified, data-rich 3D model, project teams can integrate and visualize all MEP systems in a single environment. This shift from 2D to 3D isn’t just an upgrade; it’s a complete transformation of the coordination process, turning complex challenges into manageable tasks.

Key Benefits of 3D BIM Coordination

Adopting 3D BIM coordination services offers a host of advantages that directly impact a project’s timeline, budget, and overall quality. It moves problem-solving from the construction site to the design phase, where changes are less expensive and easier to implement.

Improved Clash Detection and Resolution

One of the most significant benefits is automated clash detection. In a 3D BIM model, software can automatically identify where different systems interfere with each other—for instance, a duct running through a structural beam or a pipe clashing with electrical conduits.

- Early Identification: Clashes are flagged during the design phase, long before any physical materials are ordered or installed.

- Precision: The model shows the exact location and nature of the clash, allowing for precise and informed solutions.

- Streamlined Resolution: Teams can hold virtual coordination meetings, navigating the 3D model together to resolve conflicts collaboratively and document the changes in real-time.

Enhanced Collaboration Among Stakeholders

BIM thrives on collaboration. The central 3D model acts as a single source of truth for everyone involved in the project, from architects and MEP engineers to contractors and facility managers. This shared understanding breaks down communication silos.

When all stakeholders work from the same model, decisions are made with a holistic view of the project. An electrical engineer can see how their conduit routing affects the plumber’s pipe layout, leading to more informed and cooperative planning. This collaborative environment fosters better communication and reduces the misunderstandings common in traditional projects.

Reduced Errors and Rework During Construction

Rework is a major drain on construction budgets and schedules. A simple clash discovered on-site can halt progress for days while a solution is designed, approved, and implemented. 3D BIM coordination minimizes this risk by ensuring the MEP design is fully coordinated and validated before construction begins.

With a clash-free model, contractors can prefabricate MEP components off-site with confidence. This not only speeds up installation but also improves quality and safety, as components are built in a controlled factory environment.

Better Visualization and Understanding of MEP Systems

For non-technical stakeholders, 2D drawings can be difficult to interpret. A 3D model, however, offers an intuitive and realistic view of how MEP systems will fit within the building. This improved visualization helps everyone, including building owners and investors, to understand the design intent and make better-informed decisions. They can virtually walk through the building and see the complex networks of pipes, ducts, and wires, gaining a clear picture of the final product.

Implementing 3D BIM Coordination

Transitioning to 3D BIM coordination requires the right tools, processes, and skills. Here’s a look at what’s needed to successfully implement this approach.

Software and Tools Required

Several software platforms are essential for effective 3D BIM coordination.

- Modeling Software: Tools like Autodesk Revit are used to create the detailed 3D models of the architectural, structural, and MEP systems.

- Coordination Software: Autodesk Navisworks Manage is the industry standard for aggregating models from different disciplines, performing clash detection, and managing the resolution process.

- Collaboration Platforms: Cloud-based platforms like BIM 360 or Trimble Connect allow teams to share models and communicate in real-time, regardless of their physical location.

Best Practices for Modeling and Coordination

To get the most out of these tools, teams should follow established best practices:

- Establish a BIM Execution Plan (BEP): This document outlines the goals, standards, and responsibilities for the project, ensuring everyone is on the same page.

- Define Levels of Development (LOD): Specify how much detail is required for model elements at each project stage to avoid rework and confusion.

- Regular Coordination Meetings: Schedule frequent meetings to review clash reports and resolve issues collaboratively.

Training and Skill Development

The success of 3D BIM coordination ultimately depends on the people using the tools. It’s vital to invest in training for team members to develop their skills in BIM software and collaborative workflows. Many firms choose to partner with experienced providers like Chudasama Outsourcing to leverage specialized expertise and ensure a smooth implementation process.

Case Studies: Real-World Success

The theoretical benefits of 3D BIM coordination are proven by its successful application in countless projects worldwide.

Consider a large-scale hospital project, where MEP systems are exceptionally complex. By using 3D BIM coordination, the project team was able to identify and resolve over 10,000 clashes before construction began. This proactive approach saved an estimated 15% on rework costs and kept the project on its aggressive schedule.

In another example, a commercial high-rise project used BIM for off-site prefabrication of MEP modules. The clash-free model gave the contractor the confidence to build entire multi-trade racks in a factory. These modules were then transported to the site and installed, reducing on-site labor time by 30% and significantly improving worker safety.

The Future of MEP Management

3D BIM coordination is no longer a luxury—it is an essential component of modern, efficient project management. By moving clash detection and resolution to the digital realm, teams can prevent costly errors, improve collaboration, and deliver higher-quality buildings on time and within budget. The clarity and foresight it provides are invaluable in navigating the complexities of MEP systems.

As technology continues to advance, the role of BIM will only expand. If you’re looking to bring this game-changing advantage to your next project, it’s time to explore professional 3D BIM coordination services. Companies like Chudasama Outsourcing provide the expertise and support needed to fully leverage the power of BIM and transform your project delivery.