In today’s fast-paced construction environment, efficiency, safety, and accuracy are vital to successful project delivery. The adoption of advanced systems like the modular wall column formwork system and the slab Tableform system has revolutionized how concrete structures are built. These systems reduce labor dependency, accelerate construction timelines, and improve surface finishes while maintaining structural integrity.

As urban infrastructure expands, especially in high-rise and commercial segments, formwork technology must keep pace. Companies like Biiformtek, through their advanced Acierise product range, offer construction solutions that combine innovation, strength, and reusability—perfect for modern builders seeking reliable outcomes.

What Is a Modular Wall Column Formwork System?

A modular wall column formwork system is a pre-engineered panel-based system used to cast vertical elements such as walls, columns, and lift cores. The panels are made from steel or aluminum and are easily assembled on-site using clamps, pins, and connectors. Designed for reuse over multiple construction cycles, this system ensures fast assembly, better surface finish, and dimensional accuracy.

Thanks to its modularity, the system can be reconfigured to suit different project requirements without the need for complex carpentry or material waste. These advantages make it ideal for high-rise buildings, infrastructure projects, and repetitive vertical structures.

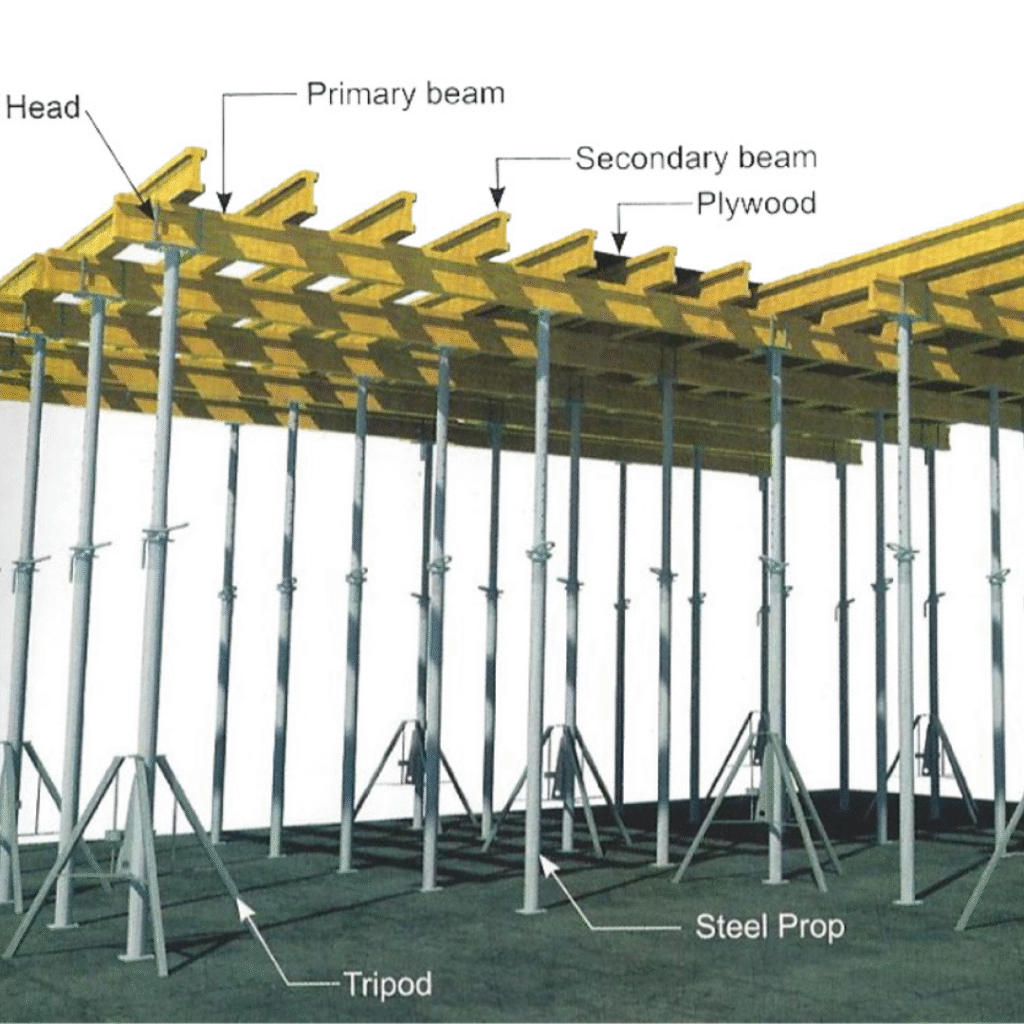

Understanding the Slab Tableform System

The slab Tableform system is designed for casting large floor slabs with minimal labor and crane time. It consists of large pre-assembled tables supported by props, which can be rolled into position for slab casting. After curing, the system is moved to the next floor using cranes or special trolley systems, making it highly efficient in multi-storey construction.

Tableform systems are perfect for large repetitive projects like commercial buildings, hotels, hospitals, and residential towers. They reduce the number of joints in the slab, speed up cycles, and produce flat, uniform slab surfaces that require minimal finishing.

Key Benefits of Modular Wall Column Formwork Systems

- Reusability and Longevity

These systems are made from robust metals like steel and aluminum, allowing up to 100 reuse cycles with minimal wear and tear.

- Faster Assembly

Panels are easy to align and lock together, significantly reducing shuttering time compared to traditional wooden formwork.

- Superior Surface Finish

Smooth, factory-finished panels produce high-quality concrete surfaces, reducing the need for plastering or other finishing.

- Reduced Labor Costs

Minimal carpentry and simplified handling mean fewer skilled workers are required on-site.

- Precision and Uniformity

Engineered to exact specifications, the system maintains uniform wall and column dimensions throughout the project.

Key Benefits of the Slab Tableform System

- Large Area Coverage

Each Tableform can cover a significant area of slab in one setup, minimizing setup time and increasing productivity.

- Improved Safety

The system includes built-in safety features like edge protection, working platforms, and integrated access ladders.

- Quick Repositioning

Once the concrete sets, the entire system can be moved horizontally and vertically without dismantling—saving valuable time.

- Consistent Results

With minimal joints and deflections, the slab finish is cleaner and more accurate, reducing post-casting work.

- Cost-Effective

Fewer materials, fewer joints, faster cycles, and less labor combine to deliver excellent ROI for contractors.

Why Choose Biiformtek’s Acierise Systems?

Biiformtek’s Acierise product line features advanced modular wall column formwork systems and slab Tableform systems designed for India’s diverse construction landscape. Engineered with durability and efficiency in mind, these systems help contractors meet tight deadlines while maintaining global quality standards.

Biiformtek’s Advantages:

- Custom-Designed Panels: Tailored for each project’s size, shape, and load requirements.

- Quality Raw Materials: Use of high-grade steel and aluminum ensures strength and longevity.

- Integrated Accessories: From props to tie rods and connectors, everything is designed for compatibility.

- Technical Support: In-house engineering and site training ensure smooth implementation.

- Fast Logistics: Timely delivery and responsive support across India.

Whether you’re constructing residential towers, commercial complexes, or public infrastructure, Biiformtek’s formwork solutions are reliable and scalable.

Real-World Applications

High-Rise Residential Buildings

Formwork speed and slab quality are critical. Tableform systems allow floors to be completed in as little as 7 days per cycle, while modular wall formwork ensures dimensionally accurate walls and columns.

Office & Commercial Complexes

Fast-paced timelines demand flexible and reusable formwork. Biiformtek’s systems adapt to different floor heights and configurations with minimal adjustments.

Infrastructure Projects

From metro stations to airport terminals, formwork systems must handle high loads and complex geometries. Modular wall column formwork systems can be adapted for large retaining walls, tunnels, and cores.

Traditional vs. Modern Formwork Systems

| Feature | Traditional Timber Formwork | Modular Wall Formwork System | Slab Tableform System |

| Material Used | Timber/Plywood | Steel/Aluminum | Steel/Aluminum |

| Lifespan (Reuse Cycles) | 5–10 times | 50–100 times | 100+ times |

| Surface Finish | Average | Excellent | Excellent |

| Labor Requirement | High | Moderate | Low |

| Assembly Time | Long | Short | Short |

| Safety | Low | High | Very High |

| Cost Over Time | High | Low | Low |

As seen in the table, traditional systems lag behind in almost every metric. Modular and Tableform systems save time, reduce labor, and enhance safety—all while improving the quality of the final structure.

Implementing Formwork Systems Effectively

To maximize benefits from these systems, here are a few expert tips:

- Early Planning: Engage with Biiformtek’s design team during project planning to align structure dimensions with formwork module sizes.

- Site Training: Train site workers on handling, assembly, and safety practices for optimal performance.

- Maintenance: Clean and store panels correctly after each use to prolong their lifespan.

- Schedule Coordination: Align crane availability and formwork cycles to prevent construction delays.

Sustainability and Environmental Impact

Modern formwork systems also support sustainable construction practices. Since modular wall column formwork systems and slab Tableform system are reusable and produce minimal waste, they reduce dependency on timber, lower material consumption, and help projects achieve green building certifications.

Conclusion

The construction sector is shifting from traditional, labor-heavy methods to faster, safer, and more efficient technologies. The modular wall column formwork system and slab Tableform system are perfect examples of this evolution—combining precision engineering with practical on-site advantages.

With industry leaders like Biiformtek offering cutting-edge solutions under their Acierise brand, developers and contractors can streamline their construction process, improve project quality, and reduce costs across the board.

Ready to Upgrade Your Construction Game?

👉 Explore Biiformtek’s formwork systems now:

https://biiformtek.in/products/acierise/