Hafnium tetrachloride is a chemical compound that often goes unnoticed outside of scientific and industrial circles. Yet, this material plays a crucial role in producing hafnium metal, which is highly valued for its strength, heat resistance, and ability to absorb neutrons. Without hafnium tetrachloride, many technologies in energy, aerospace, and electronics would face serious challenges.

This article will explore the nature of hafnium tetrachloride, its properties, how it is produced, its uses, and why it is considered a building block for advanced applications.

What is Hafnium Tetrachloride?

Hafnium tetrachloride, with the chemical formula HfCl₄, is an inorganic compound consisting of one hafnium atom bonded to four chlorine atoms. It typically appears as a white crystalline solid. One of its most notable features is that it is highly sensitive to moisture. When exposed to humid air, it reacts quickly, producing hydrogen chloride gas and hafnium oxide.

This sensitivity means it must be handled carefully, usually in tightly controlled environments where moisture is excluded. Despite its instability in open air, hafnium tetrachloride remains one of the most important hafnium-based compounds.

Physical Characteristics

Hafnium tetrachloride displays several interesting physical properties:

-

Appearance: White to gray solid crystals

-

Melting and Boiling: It melts and boils at relatively moderate temperatures compared to metals, making it easier to convert into vapor form

-

Volatility: The compound is volatile when heated, allowing it to be used in vapor-based processes

-

Moisture Sensitivity: Quickly breaks down in the presence of water or humidity

Its volatility and reactivity make it particularly useful in industrial processing, but also demand strict handling procedures.

Chemical Behavior

From a chemical standpoint, hafnium tetrachloride is highly reactive. Its behavior includes:

-

Hydrolysis: It reacts strongly with water, forming hafnium oxide and releasing corrosive hydrogen chloride gas.

-

Precursor for Other Compounds: It serves as a starting material for synthesizing a wide range of hafnium-based chemicals.

-

Ability to Vaporize: Its capacity to enter a gaseous state under controlled heating makes it valuable in thin-film production.

This chemical reactivity explains why hafnium tetrachloride is so central in producing other hafnium materials.

How is Hafnium Tetrachloride Produced?

The production of hafnium tetrachloride usually begins with ores that contain both zirconium and hafnium. These two elements occur together in nature and are very difficult to separate due to their similar chemical behavior.

The steps in making hafnium tetrachloride typically include:

-

Chlorination of Raw Material: Hafnium oxide or hafnium metal is treated with chlorine gas at high temperatures, often with carbon as a reducing agent. This forms hafnium tetrachloride.

-

Separation from Zirconium: Since zirconium tetrachloride forms at the same time, advanced separation techniques such as fractional distillation or solvent extraction are required.

-

Purification: The hafnium tetrachloride is purified to obtain a product suitable for further processing.

This process is essential because only after obtaining pure hafnium tetrachloride can hafnium metal be extracted for industrial use.

Uses of Hafnium Tetrachloride

1. Source of Hafnium Metal

The most significant use of hafnium tetrachloride is in the production of metallic hafnium. By reducing hafnium tetrachloride with magnesium or sodium, industries obtain pure hafnium metal. This step is a part of the Kroll process, a method also used in titanium production.

2. Nuclear Technology

Hafnium metal derived from hafnium tetrachloride is an excellent neutron absorber. This property makes it highly valuable in nuclear power plants, where it is used in control rods that regulate the chain reaction within reactors.

3. Aerospace and Defense

Hafnium is used in superalloys that must withstand extreme conditions. Alloys containing hafnium are used in jet engines, rocket parts, and other high-stress environments. The ability to resist heat and corrosion makes hafnium-based materials superior in these applications.

4. Electronics and Semiconductors

Hafnium oxide, obtained from hafnium tetrachloride, has become an essential material in the semiconductor industry. It serves as a high-k dielectric in microchips, helping to improve the performance and efficiency of modern processors.

5. Chemical Vapor Deposition (CVD)

Hafnium tetrachloride is widely used in vapor deposition techniques to create thin films of hafnium-based compounds. These thin films are used in electronics, optics, and protective coatings.

6. Research Applications

In research settings, hafnium tetrachloride is used to create new compounds and materials. Its strong reactivity allows scientists to explore new chemical pathways and advanced material designs.

Safety Measures

Although hafnium tetrachloride is valuable, it must be handled with extreme care. Exposure to air or moisture can release hydrogen chloride gas, which is corrosive and dangerous to breathe.

Safety precautions include:

-

Handling the compound in sealed, moisture-free environments

-

Using gloves, safety glasses, and protective clothing

-

Ensuring good ventilation in laboratories and industrial sites

-

Storing in airtight containers away from water and humidity

Proper handling ensures that workers remain safe while still benefiting from the compound’s usefulness.

Importance in Modern Industry

Hafnium tetrachloride acts as the bridge between natural hafnium resources and the advanced materials that shape modern technology. Without it, the production of pure hafnium metal would be far more difficult and costly.

Industries such as nuclear energy, aerospace, defense, and semiconductors rely on hafnium metal and hafnium-based compounds. Hafnium tetrachloride is the starting point for all of these, highlighting its critical role in today’s high-tech world.

Environmental Considerations

The handling of hafnium tetrachloride also raises environmental concerns. When not managed properly, its reactions can release chlorine gas and hydrogen chloride into the environment, which are harmful pollutants. For this reason, industries take strong precautions, using modern filtration and neutralization systems to minimize emissions.

Additionally, because hafnium is relatively rare, sustainable resource management is important. Recycling hafnium-containing materials and careful mining practices help ensure that future industries will continue to benefit from this unique element.

Future Outlook

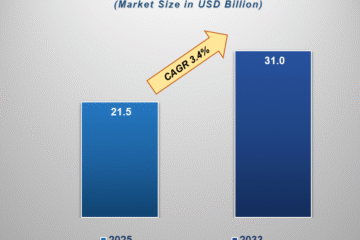

As technology advances, the demand for hafnium compounds is expected to grow. The semiconductor industry, in particular, continues to rely on hafnium oxide for improving transistor performance. Similarly, the nuclear sector depends on hafnium for safe energy production.

This means hafnium tetrachloride will remain an important industrial compound for the foreseeable future. Research may also uncover new applications in fields like nanotechnology and advanced coatings, expanding its importance even further.

Conclusion

Hafnium tetrachloride may not be widely known, but it is one of the most important chemical compounds in modern industry. Acting as the primary gateway to producing hafnium metal, it supports critical sectors such as nuclear energy, aerospace, electronics, and scientific research.

Its unique properties, from volatility to strong reactivity, make it both valuable and challenging to handle. With proper safety and environmental practices, hafnium tetrachloride continues to enable technologies that shape the modern world.

In short, while it may be hidde