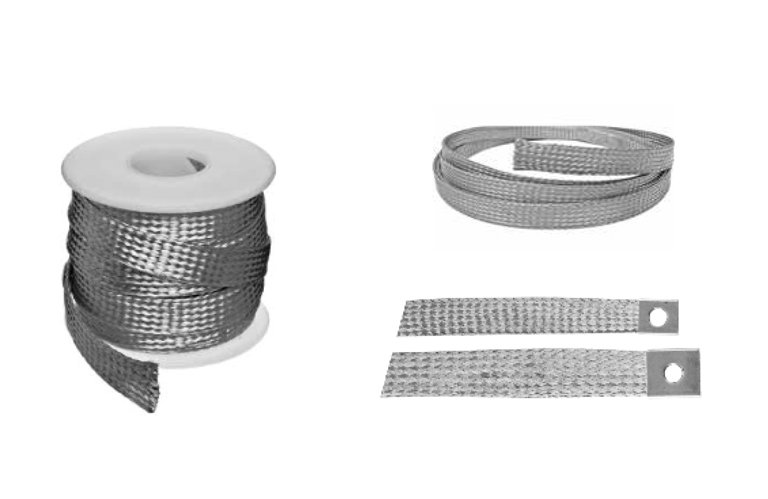

Modern electrical setups have countless electronic devices and electrical appliances. Whether it is an industry with heavy machinery or a commercial setting like a mall, the signal sensitivity has increased in the cables. Data centres, smart homes, and industrial plants have densely packed installations. Due to this, electromagnetic shielding becomes essential in these settings. Tinned Copper Braid supports this need because it provides a reliable conductive path and withstands environmental stress. It has a woven design that allows it to bend and settle into narrow spaces without weakening the conductor. This makes it a dependable choice for several critical applications. In this blog, we are going to explore the various applications of this flexible electrical conductor.

Uses of Tinned Copper Braid

Grounding Systems

Tinned copper braid is widely used because of its ability to dissipate the current safely to the ground. It provides a low impedance path for the current because of its large surface area. These are used as bonding jumpers to protect the equipment and personnel in industrial facilities and residential complexes.

Electromagnetic and Radio Frequency Shielding

These braids are woven around the cores of cables or components to block the unwanted electromagnetic interference and the radio frequency interference. This ensures signal integrity in the sensitive electronic devices. This plays a vital role in applications like data transmission and high-frequency communication where signal clarity is paramount.

Flexible Connections

Many electrical cables and wires are dynamic in nature. The flexibility of the tinned copper braid is ideal for these applications because it can handle vibrations and thermal fluctuations in the power distribution systems and busbar, and terminals. Heavy machinery and robotics use the flexibility of this copper conductor.

Automotive and Marine Wiring

The braided design adds flexibility to the copper conductor, while the tin coating protects from oxidation and corrosion. This is essentially used in the battery cablesengi e grounding straps in the automotive. The marine environments use it because of its resistance to vibration, moisture, and saltwater corrosion.

High-Temperature Environments

High heat applications like electrical furnaces, industrial ovens and others use tinned copper braid because it can evenly dissipate heat and avoid being degraded by an increase in temperature. It can perform reliably in high-heat applications where the bare copper wire strand fails.

High Current Carrying Capacity

The braided structure with a large surface area allows for efficient heat dissipation and a low-resistance path for electron flow. It enables it to handle high currents with minimal energy loss.

Conclusion

The tinned copper braid is an innovative design that has many advantages in modern electrical installations. From teh data centers to the sound recording studios, it protects the sensitive electronics from the severe electromagnetic interference by absorbing the energy and dissipating it. It redirects the interference away from the sensitive circuit. The overall application includes grounding, bonding, connecting power distribution systems and carrying high current. Its flexibility, resistance to corrosion, and ability to protect signals make it suited for both heavy industrial work and advanced electronic systems.