Openhole Whipstock is a specialized directional drilling tool widely used in the oil and gas industry to create a new wellbore path from an existing open hole. It plays a crucial role in sidetracking operations, allowing operators to bypass obstructions, access new reservoirs, or correct well trajectory without casing installation. Progrynd’s Openhole Whipstock is engineered to deliver precision, reliability, and operational efficiency in challenging drilling environments.

What is an Openhole Whipstock?

An Openhole Whipstock is a wedge-shaped mechanical device set inside an uncased (open) wellbore. It provides a solid deflection surface that guides the drill bit in a new direction. Unlike cased-hole whipstocks, openhole whipstocks are deployed directly in the formation, making them ideal for early-stage or corrective drilling operations.

Key Components of Openhole Whipstock

An Openhole Whipstock system typically consists of:

• Whipstock Body – A hardened, inclined surface that deflects the drill bit.

• Anchor System – Secures the whipstock firmly in the formation.

• Orientation Mechanism – Ensures accurate alignment for precise sidetracking.

• Running and Setting Tools – Used to deploy and activate the whipstock downhole.

Each component is carefully designed to withstand high pressure, temperature, and formation stress.

Applications of Openhole Whipstock

Openhole Whipstocks are used in a wide range of drilling scenarios, including:

• Wellbore Sidetracking

• Bypassing stuck or damaged sections

• Directional correction of deviated wells

• Accessing untapped hydrocarbon zones

• Cost-effective well re-entry operations

These applications help operators maximize reservoir recovery while minimizing drilling risks and costs.

Advantages of Using Openhole Whipstock

1. Cost Efficiency

Eliminates the need for casing installation before sidetracking, reducing overall operational costs.

2. Accurate Directional Control

Provides a stable and precise deflection angle for controlled drilling.

3. Time Saving

Quick deployment and setting reduce non-productive time (NPT).

4. Formation Compatibility

Designed to perform effectively in various formation types, including soft and medium-hard formations.

5. Operational Flexibility

Suitable for multiple well profiles and drilling conditions.

Why Choose Progrynd Openhole Whipstock?

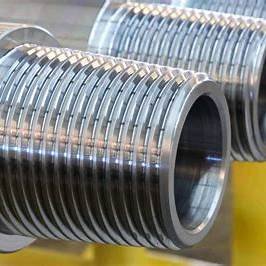

Progrynd’s Openhole Whipstock solutions are manufactured with high-grade materials and tested under strict quality standards. Our tools offer:

• Proven reliability in demanding drilling environments

• Enhanced anchoring and stability

• Precision-engineered design for consistent sidetrack results

• Compatibility with standard drilling assemblies

• Technical support and customization options

We focus on delivering tools that improve drilling performance and reduce operational challenges.

Installation and Operation Overview

The Openhole Whipstock is run into the wellbore using a drill string or wireline system. Once positioned at the desired depth, the anchor is activated to secure the whipstock. After proper orientation, the drilling assembly is introduced, and the bit follows the inclined face to initiate a new wellbore path.

Safety and Reliability

Safety is a top priority in drilling operations. Progrynd Openhole Whipstocks are designed to ensure secure setting, minimal slippage, and controlled drilling, reducing risks associated with wellbore instability and tool failure.

Conclusion

Openhole Whipstock is an essential tool for modern directional drilling and sidetracking operations. With its ability to deliver precision, efficiency, and cost savings, it remains a preferred solution for oil and gas operators worldwide. Progrynd’s Openhole Whipstock stands out as a reliable and high-performance choice, helping operators achieve successful drilling outcomes even in complex well conditions.