In today’s rapidly expanding power distribution networks, utilities and EPC contractors require cable solutions that are safe, durable, and easy to deploy in congested and urban environments. Concentric cable has become one of the most trusted designs for low- and medium-voltage underground and service distribution systems due to its compact construction and excellent electrical performance.

As a global manufacturer of overhead conductors and power cables, HNBF Power supplies high-quality concentric cables engineered for utility networks, renewable integration projects, and industrial power infrastructure worldwide. This guide explains how concentric cable works, where it is used, and why it delivers long-term value for engineers and procurement professionals.

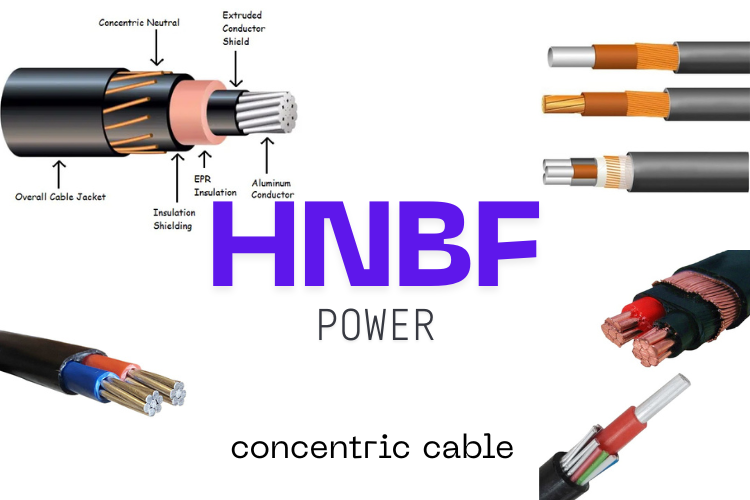

What Is a Concentric Cable?

A concentric cable is a power cable in which the phase conductor is positioned at the center and surrounded by one or more layers of helically applied neutral or grounding conductors. These surrounding wires form a concentric layer that provides both electrical and mechanical protection.

Unlike traditional single-core cables with a separate neutral conductor, concentric cable integrates the return path directly into the cable structure. This design improves safety, simplifies installation, and ensures consistent current distribution around the core.

How Concentric Cable Is Constructed

Central Phase Conductor

The core conductor is usually manufactured from aluminum or copper and is designed to carry the main load current in the distribution system. For utility applications, compact stranded aluminum conductors are widely preferred due to their favorable strength-to-weight ratio and cost efficiency.

Insulation System

The conductor is insulated using high-performance materials such as XLPE or PVC, ensuring excellent dielectric strength and long service life under harsh environmental conditions.

Concentric Neutral Layer

The key feature of a concentric cable is the outer layer of small conductors applied evenly around the insulated core. These wires act as:

-

Neutral return conductors

-

Grounding conductors

-

A protective barrier against external damage

This concentric arrangement maintains electrical symmetry and reduces electromagnetic imbalance.

Key Advantages of Concentric Cable for Utilities

1. Improved Safety and Fault Performance

The surrounding neutral wires create a controlled and reliable fault current path. In the event of insulation damage, fault currents are quickly returned through the concentric neutral, helping protective devices operate correctly and reducing public safety risks.

2. Simplified Underground Installation

Concentric cable eliminates the need for a separate neutral conductor. For underground distribution networks and service connections, this significantly reduces installation complexity and trench space requirements.

3. Consistent Electrical Balance

Because the neutral conductors are evenly distributed around the phase conductor, current flow remains balanced. This reduces localized heating and improves long-term reliability in continuous load conditions.

4. Mechanical Protection

The concentric neutral wires provide an additional protective layer, enhancing resistance to impact, compression, and handling damage during transportation and installation.

Typical Applications of Concentric Cable

Urban Underground Distribution Networks

Concentric cable is widely used in city distribution systems where compact routing and high safety standards are mandatory.

Service Drops and Utility Connections

For commercial and residential service connections, concentric cable offers a robust and standardized solution with integrated grounding.

Renewable and Infrastructure Projects

Modern solar and energy infrastructure projects increasingly rely on concentric cable to meet strict electrical safety and grounding requirements.

Industrial Power Systems

In factories, logistics centers, and processing plants, concentric cable ensures stable power delivery while maintaining compliance with grounding and protection standards.

Concentric Cable vs. Traditional Neutral Cable Designs

| Feature | Concentric Cable | Separate Neutral System |

|---|---|---|

| Installation time | Faster | Slower |

| Cable routing | Compact | Requires additional conductor |

| Fault current path | Integrated | Separate grounding conductor |

| Mechanical protection | Higher | Lower |

From a procurement perspective, the total installed cost of concentric cable is often lower due to reduced labor, simpler accessories, and fewer installation steps.

Engineering Considerations When Selecting Concentric Cable

Current Carrying Capacity

Engineers must evaluate both the phase conductor size and the total cross-section of the concentric neutral to ensure adequate fault current capability.

Soil and Environmental Conditions

For buried installations, soil thermal resistivity, moisture levels, and corrosive conditions should be assessed to determine insulation material and sheath requirements.

Compliance and Standards

Concentric cables are typically manufactured to recognized international and utility standards such as those issued by International Electrotechnical Commission and ASTM International, ensuring interoperability and regulatory compliance across different regions.

Why Engineers and Utilities Choose HNBF Power Concentric Cable

HNBF Power designs and manufactures concentric cable solutions specifically for utility-scale distribution and infrastructure projects. With advanced production lines and strict quality control, the company delivers consistent conductor geometry, reliable insulation performance, and precisely applied concentric neutral layers.

Beyond standard designs, HNBF Power also supports:

-

Custom conductor sizing for utility specifications

-

Tailored insulation and sheath materials for regional climates

-

Utility-approved packaging and delivery solutions for large EPC projects

By integrating concentric cable into its complete portfolio of AAC, AAAC, ACSR, ABC, LV power cable, and concentric cable systems, HNBF Power enables utilities to source multiple products from a single technically qualified supplier.

Frequently Asked Questions (FAQs)

What is the main purpose of the concentric neutral layer?

The concentric neutral provides a reliable return and grounding path while improving fault current handling and enhancing installation safety.

Is concentric cable suitable for direct burial?

Yes. When designed with appropriate insulation and sheath materials, concentric cable is widely used for direct burial and underground duct installations.

Can concentric cable be used for both residential and utility networks?

Absolutely. It is commonly used for residential service drops as well as utility-scale underground distribution systems.

How is concentric cable different from armored cable?

Concentric cable focuses on electrical symmetry and integrated neutral grounding, while armored cable mainly provides mechanical protection through metallic armor layers.

Power Your Distribution Projects with HNBF Power

Selecting the right concentric cable directly affects network reliability, safety, and long-term operating cost. Whether you are designing a new underground distribution system, upgrading aging service networks, or sourcing cable for large EPC projects, HNBF Power delivers technically proven and utility-approved concentric cable solutions.

Contact HNBF Power today to discuss your project requirements and receive customized concentric cable solutions tailored to your power distribution network.