Counter Balance Electric Stacker – An Efficient Solution for Heavy-Duty Material Handling

In today’s fast-paced industrial environment, efficient material handling plays a crucial role in productivity, safety, and cost control. With growing warehouse automation and increasing demand for faster operations, industries are shifting toward electrically powered equipment. One such advanced solution is the Counter Balance Electric Stacker, which combines strength, stability, and maneuverability to handle demanding material handling tasks.

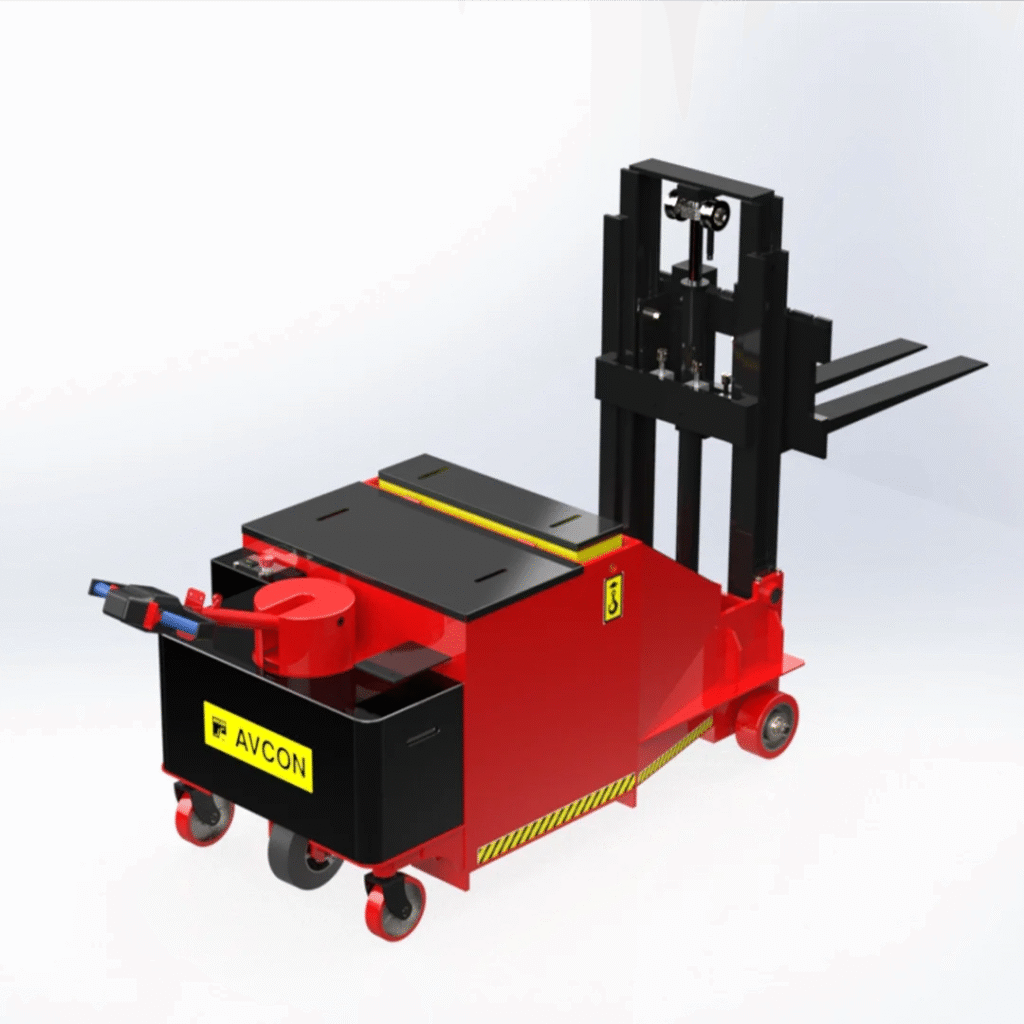

Designed for lifting, transporting, and stacking loads without the need for support legs, the counter balance design allows operators to work efficiently even in confined spaces. Leading manufacturers and suppliers across India, including established names such as Avcon Systems, develop counter balance electric stackers that meet modern industrial requirements.

What Is a Counter Balance Electric Stacker?

A Counter Balance Electric Stacker is a battery-powered lifting machine that uses a rear counterweight to balance the load instead of front stabilizing legs. This design allows direct pallet pickup and unloading, making it ideal for applications where floor space is limited.

Unlike conventional stackers, counter balance stackers provide:

-

Greater flexibility

-

Easy pallet access

-

Fully electric lifting and driving

-

Enhanced operator control

They are commonly used where forklifts may be too large or impractical.

Why Industries Choose a Counter Balance Electric Stacker

Industries across India prefer counter balance electric stackers for several practical reasons:

✔ No Support Legs Required

The counterweight design allows easy handling of closed pallets and containers.

✔ Compact and Space-Saving Design

Ideal for narrow aisles, loading bays, and confined storage areas.

✔ Fully Electric Operation

Battery-powered drive and lift systems reduce manual effort and increase efficiency.

✔ Improved Load Stability

The counterbalance ensures stable lifting and smooth movement even with heavier loads.

✔ Lower Operational Cost

Electric operation reduces fuel consumption, maintenance, and labor costs.

Technical Features of a Counter Balance Electric Stacker

High-quality counter balance electric stackers share several advanced technical features:

1. AC Drive Motor Technology

Provides high torque, energy efficiency, smooth acceleration, and low maintenance requirements.

2. Fully Electric Hydraulic Lifting System

Ensures precise lifting, controlled lowering, and minimal vibration during operation.

3. Load Capacity and Lifting Height

Typical industrial specifications include:

-

Load Capacity: 1000 kg to 2000 kg

-

Lifting Height: Up to 4.5 meters (model dependent)

4. Maintenance-Free Battery System

-

Long operating hours per charge

-

Reliable performance during continuous shifts

-

Safe and eco-friendly operation

5. Ergonomic Tiller Handle

Equipped with:

-

Forward and reverse controls

-

Speed adjustment

-

Horn and emergency reverse switch

-

Electromagnetic braking

6. Reinforced Mast and Chassis

Ensures structural strength, durability, and long service life under heavy-duty use.

Advantages of Using a Counter Balance Electric Stacker

✔ High Maneuverability

Allows smooth movement in narrow aisles and congested workspaces.

✔ Increased Productivity

Reduces handling time and improves workflow efficiency.

✔ Operator Safety and Comfort

Ergonomic controls reduce fatigue and improve handling precision.

✔ Zero Emissions

Battery operation ensures clean and quiet performance indoors.

✔ Reduced Maintenance

Fewer moving parts and robust electric components lower maintenance costs.

Applications of Counter Balance Electric Stacker

The Counter Balance Electric Stacker is widely used in:

1. Manufacturing Units

For moving raw materials, components, and finished goods.

2. Warehouses and Distribution Centers

Used for stacking pallets and organizing inventory efficiently.

3. Logistics and Transport Hubs

Ideal for loading and unloading goods in tight spaces.

4. Retail and Wholesale Storage Areas

Helps manage stock movement quickly and safely.

5. Engineering and Automotive Industries

Handles heavy and precision components with ease.

Safety Features of a Counter Balance Electric Stacker

Modern electric stackers are equipped with advanced safety systems, including:

-

Emergency stop button

-

Overload protection

-

Anti-rollback braking system

-

Speed reduction on turns

-

Mast stability controls

-

Automatic power cut-off

These features ensure safe operation even during extended working hours.

How a Counter Balance Electric Stacker Improves Operational Efficiency

The adoption of a counter balance electric stacker significantly enhances daily operations by:

➤ Reducing manual handling risks

➤ Minimizing load handling time

➤ Supporting continuous shift operations

➤ Allowing precise pallet placement

➤ Optimizing warehouse space utilization

These advantages make it a reliable solution for growing industrial setups.

Selecting the Right Counter Balance Electric Stacker Manufacturer in India

While choosing a counter balance electric stacker, businesses should evaluate:

-

Product quality and certifications

-

Battery performance and charging efficiency

-

Load capacity options

-

Customization capabilities

-

After-sales support and service network

Manufacturers such as Avcon Systems are recognized for offering robust, application-specific material handling solutions suitable for diverse industrial needs across India.

Conclusion

The Counter Balance Electric Stacker is a versatile and powerful solution for modern material handling requirements. With its compact design, electric efficiency, superior load stability, and enhanced safety features, it serves as an excellent alternative to traditional forklifts and manual stackers. From warehouses to manufacturing plants, this equipment helps improve productivity, reduce operational costs, and create safer working environments.

As industries continue to prioritize automation and efficiency, counter balance electric stackers will remain a key component in advanced material handling systems across India.